Call Us

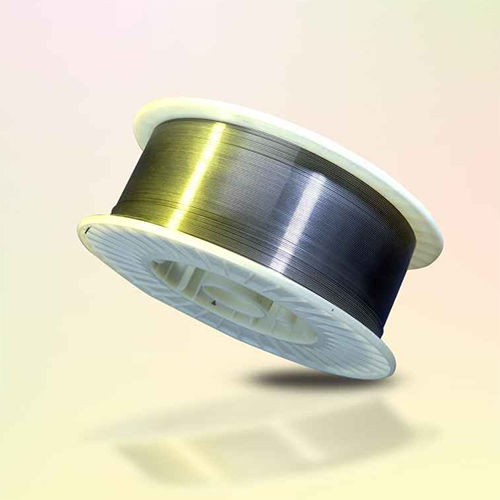

ROYALFIL GS-91B9

Product Details:

- Product Type Cable Wire

- Material Low Alloy Steel

- Usage Industrial

- Color Silver

- Warranty 1 Year

- Click to View more

ROYALFIL GS-91B9 Price And Quantity

- 20 Kilograms

- 1722 INR/Kilograms

ROYALFIL GS-91B9 Product Specifications

- Silver

- Low Alloy Steel

- Industrial

- 1 Year

- Cable Wire

ROYALFIL GS-91B9 Trade Information

- 5000 Kilograms Per Month

- 7 Days

Product Description

Applications Royalfil GS-91B9 is recommended for welding of ASTM A213-T91 tube, A335 - P91 pipe, A 182/A336 F91 forgings, A217 C12 A castings, A234 WP91 & A369 FP91 type material. Widely used for components such as headers, main steam piping and turbine castings, power generation plant, oil refineries, coal liquefaction and gasification plants.

Characteristics on Usage Royalfil GS-91B9 is martensitic alloy type all position Rutile based flux cored wire depositing approx 9% Cr, 1.00% Mo, 0.5% Ni, weld metal with CO2 shielding. The slag coverage is complete & easily removable. The weld metal is of radiographic quality In PWHT condition, microstructure consists of tempered martensite with alloyed carbides. Thermal treatment is critical and must be controlled. The temperature at which the microstructure has complete transformation into martensite is relatively low. Therefore after welding is completed, it is recommended to cool down weldment to atleast 93 deg C to maximize transformation to martensite. Mn + Ni % in the weld should not exceed 1.50% (Typical value - 1.20%). By restricting the Mn + Ni%, PWHT temperature will be sufficiently below the lower transformation temperature to avoid the partial transformation of microstructure.

Packing 15 Kgs. Vacuum packed plastic spool.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese