Call Us

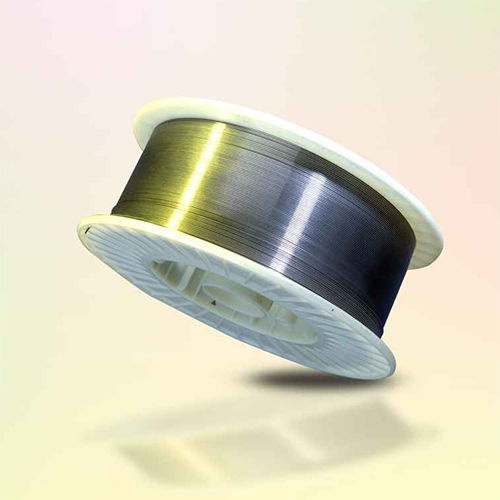

ROYALFIL GS - 2553

Product Details:

- Product Type Cable Wire

- Material Stainless Steel

- Usage Industrial

- Color Silver

- Warranty 1 Year

- Click to View more

ROYALFIL GS - 2553 Price And Quantity

- 5510 INR/Kilograms

- 20 Kilograms

ROYALFIL GS - 2553 Product Specifications

- Cable Wire

- Silver

- Industrial

- Stainless Steel

- 1 Year

ROYALFIL GS - 2553 Trade Information

- 5000 Kilograms Per Month

- 7 Days

Product Description

Applications Royalfil GS- 2553 is used for welding of duplex stainless steels with 25% Chromium. Also used for joining of Duplex steels to mild steels, cladding of duplex stainless steel welld metal on carbon steel / low alloy steel. Used for piping in gas & oil industry, off-shore platforms, chemical and petrochemical plants, pulp/paper and textile industries, welding of duplex stainless steels 1.4417, 1.4460, 1.4462, 1.4515, 1.4517.

Characteristics on Usage Royalfil GS- 2553 is a Duplex stainless steel fluxcored welding wire for welding with Co2 shielding gas. The nominal combination of the weld metal is 25.5% Cr, 9.5% Ni, 3.4% Moly, 2% Cu and 0.18% N. The microstructure of the weld deposit consists of a mixture of austenite and ferrite. Because of two phase microstructure, this alloy is one of the family of duplex stainless steel alloys. Addition of Copper improves corrosion resistance in sulphuric acid media and potentially increases strength and wear resistance. Welding of duplex stainless steel should be made with low heat input. Weld metal is of radiographic quality.

Packing 12.5 Kgs. vacuum packed plastic spool

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese